|

TMX 35mm CARBS

By Randy Norian

Swapping 35mm carbs onto the RG500 seems like a logical modification. Most

125 MX bikes come standard with a 35mm carb, and 125 GP bikes use up to a 38mm

carb. Ultrathin slide carbs on MX bikes generally have terrific throttle

response, so it isn't unrealistic to expect good driveability on the RG when

fitted with 35mm TMX carbs or their Keihin equivalent.

It's been a few years since I made this modification, so this will just cover

the basics as I remember them.

Just how much power is this mod worth? I didn't dyno the bike at that time,

way back in those days I was timing 60-120 mph intervals (2 way average) to

sort out my tuning. Before this mod, I timed 2 way average of 8.49 seconds,

60-120 mph. I backed this up with a 120.96 mph quarter mile pass.

After the 35mm carbs were installed, 60-120 average dropped to 7.22 seconds,

and quarter mile speed increased to 124.5 mph. The motor simply made more

power at the same rpms than before. I was able to go faster while shifting at

the same point, or sooner, although there -was- a slight gain in peak rpms

that the motor would turn.

Driveability is excellent. Throttle response is good, and the bike still

gets about 30 mpg when ridden moderately. It will accept full throttle as low

as 4500 rpm; if anything, the bike rides better with the big carbs than it did

before.

35mm carbs have 1.56x the area of 28mm carbs, so this is a huge increase in

inlet area.

TMX carbs are a primary-type main fuel circuit, as opposed to the stock carbs'

bleed-type circuit. TMX carbs have a very thin slide and generate a strong

signal at the venturi, so the have excellent throttle response, even when

using a large carb on a small motor. Early TMXs like mine do not have

removeable needle jets, allowing you to only change the needle to tune. Later

models are fully tuneable.

35TMXs are physically large. They are taller and deeper than the *tiny* stock

carbs.

This is not a simple bolt on-- it's not terribly difficult, but there are

obstacles.

The stock carbs have area of 6.15 cm2. The stock port size at the inner disc

cover is about 8.2 cm2. The port has a max width of about 24.3mm and max

height of about 38.4mm. The stock port is 52 degrees wide. With a stock

disc, you have 1174 degrees x cm2 of open time-area.

The port is partially open for the first (and last) 52 degrees of the intake

event.The port is fully open for the duration of the disc cutaway, minus the

width of the port. Example: The stock disc has about 143 degrees of cutaway.

It is fully open for 143-52 = 91 degrees. However, the port is half open

during both the opening and closing phases. Averaged out, that gives another

52 degrees of effective full-open time-area. 91 + 52= 143 degrees. 143

degrees x 8.21 cm2 = 1174 degrees x cm2. The port is full or partially open

for 195 degrees.

The effect is this: the port is fully open for the length of the disc cutaway.

Total inlet duration is cutaway + port width (in degrees) . An increase in

effective time area comes from the increase in AREA of the port, not the width

of the port.

The TMX35 carbs have area of 9.62 cm2. In addition to installing the larger

carbs, I enlarged the passage through the cases to match the carbs. My

enlarged port is 44.4mm wide at its maximum and 27.8 mm tall, max. My

enlarged port has a sectional area of 10.2 cm2. This gives an intake time-

area of 1461 degrees X cm2. This port is fully open (with a 143 degree

cutaway) for only 86 degrees. However, it is partially open for the first and

last 57 degrees. Effective full-open duration, 143 degrees. So, there are 143

+ 57 degrees of full or partially open rotation, for a total of 200 degrees

open duration. But still only 143 degrees of effective full-open time.

One more example. We create a port that is 100 degrees wide. It is fully

open for 143 - 100 = 43 degrees. the rest of the time it is partially obscured

by the disc. There are 100/2 + 100/2 degrees of 'half open' port. Effective

full-open time is still 143 degrees. Got it? The increase comes from the

larger port area, not the increased disc duration (which would now be 243

degrees of intake duration).

Ideally we would like a very tall inlet port, with small port width (in

degrees). This is accomplished by using the largest diameter disc valve

possible. Then we could have large intake time-area, with conservative total

disc duration.

The result of all this fooling around is that my large carbs/ ports have a

slight increase in port-open timing compared to stock, but a huge increase in

intake time area. A small port motor with 159 degree disc cutaway will have

211 degrees of disc-open timing, but only 1305 degrees x cm2 of intake time

area. My motor can use a stock disc, have only 200 degrees of disc-open

timing, and still have 1461 degrees x cm2 intake time-area. Sort of like a 4

valve motor vs a 2 valve motor. I think this is part of the key to the

excellent torque at low rpms that we are getting from my motor (500cc but 66

ft-lbs).

Back to carbs!

I bought all 4 carbs through Sudco Mikuni in California. This set me back

about 600 bucks, although I hear these carbs are down to 100$ apiece these

days.

I bought rubber spighot adaptors to attach the carbs to the engine, also

through Sudco Mikuni.

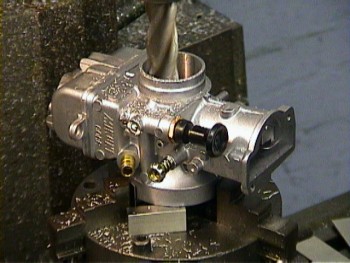

I split the cases and enlarged the ports through the case, to the dimensions

mentioned earlier.

Templates made to grind ports, left side

has been done, the right side shows how much material has to be removed

|

At the inlet, the openings were enlarged to about the

outer edge of the O-ring recess. I bolted the spighot adaptors on and used a

little sealant, except for the left rear carb (the alternator carb). On that

cylinder, I installed a 1/4 inch deep wedge-shaped spacer to tilt the carb up

and out a little to clear the alternator case. I also ground a small divot in

the alternator cover to clear the lower drain plug on that carb. TMX carbs

have quick change plugs on the float bowls that allow you to change main jets

in just a few minutes, without removing the carbs.

TMX carbs are designed to function normally while tilted, I believe they are

good to at least 10 degrees tilt off-axis.

I sourced miniature hose barb fittings from a hobby shop; the fittings were

designed for use on fuel lines on RC planes. Drilled and tapped the fittings

into the carb throats for the oil injection lines, and installed check valves

inline to prevent the oil tank from siphoning into the carbs.

I swapped the stock SIPC (crossover) tube onto the 35mm carbs, with no

noticeable effect. I think the 35mm carbs are sufficiently large that this

feature is not necessary any longer.

The stock throttle pull is enough to fully open the carbs (just barely),

however there is not enough exposed cable sticking out the ends of the

throttle cables for the slides to close all the way. You need to cut away

some of the coiled sheathing to allow more of the cable to stick out. I heat

the cap with a propane torch and then pull the metal endcap away with a pair

of pliers. Bend the cable over to spread out the coils and cut it with a

pair of snips or something. I used a dremel, but be VERY CAREFUL!!!! if you

slip and nick the cable, you will have little frayed strands sticking out and

grabbing onto things, at best it will be annoying and at worst it can make the

throttle hang up. I stretch out the now floating length of coil and 'unwind'

it from the cable. I then smooth the shortened coiled end and reattach the

metal encap, with a touch of heat. Too much will make the cable cover wad up.

Now you have 35mm carbs installed, but they were designed to be used one at a

time, on a dirtbike. A set of four of these will have a truly amazing

throttle pull. You'll have a grip that can crush mortal bones in just a few

short weeks of riding this setup.

I took a set of low-rate springs from a set of CV carbs slides and rewound

them for use in the TMX carbs. They have plenty of tension to drop the

slides, but allow for a light throttle pull when all 4 are ganged together.

Jetting: The TMXs flow lots of fuel with very little signal. On a disc valve

motor, the intake *pop* really gets the gas moving. I had to jet the carbs

down severly in order to get them to run on my bike. They came with jets in

the high 300 range installed, I had to drop into the 270 range to get them to

work on my bike. I dropped to a #10 pilot jet, and kept going leaner on the

needles until I was 2 needles leaner than what came on the carbs. I use a

6EN11-58 needle, middle position. This setup ought to get you running in the

ballpark. The tiny pilots indicate that we are getting a much stronger

metering signal, though conventional wisdom says that big carbs carburete

poorly. The TMX carbs are a generation ahead of TMs in this respect, I think.

Why not bore them even bigger? |

Intake: I tried to use the stock intake trunks, which had worked very well for

me up to this point, but they are too small for the 35mm carbs and the carbs

go very rich at top rpms. Removing the trunks was necessary to get the TMX

carbs to run. I made airboxes on each side of the motor early on, however now

I use 4 individual filters. I will use a semienclosed, fresh air fed airbox

as soon as I can make one, as power drops 1% with every 10 degree F. increase

in inlet air temperature. I suppose you can choose whether to pursue this

free HP or not.

That ought to cover the basics! Have fun!

Randy Norian

|