|

| |

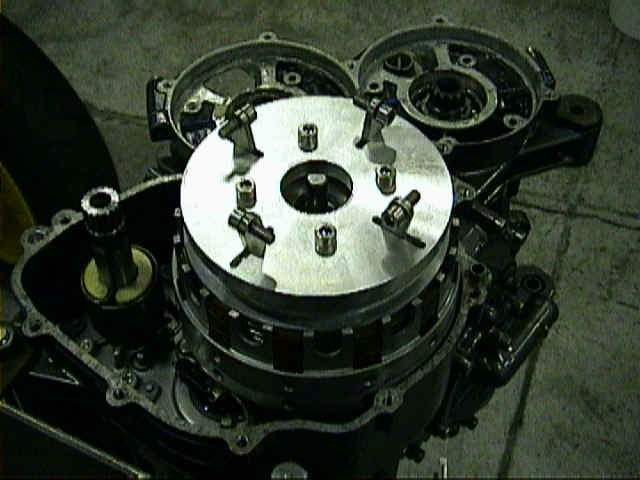

LOCK-UP CLUTCH

|

I had come across a big problem once i had

started to make a lot of torque, this was the fact that the clutch could not cope with the

power that was now being transmitted through it, resulting in alot of slippage at aound

7500rpm.

Heavy duty clutch springs were installed and oil passages added to the inner and outer

clutch basket, just to try and get more oil flow through the plates, This was kind of a

success, but the pressure needed to pull the clutch lever was "beyond stupid",

and the clutch still slipped occasionally.

Enter Drag Racing technology - I work on alot of 300bhp+ drag bikes, they dont have clutch

problems and i'm only putting through half the Hp that they are transmitting through the

clutch.

Lock-up clutches work by centrifugal force, forcing the weighted arms against the clutch

assembly, this in turn applys pressure to the plates to stop them slipping.

Simple i'll machine one up! |

|

Well maybe not quite so simple, biggest

promlem was the kick start shaft, as the clutch was now 50mm higher, the clutch cover had

to also be spaced out an extra 50mm, so an adaptor was made to fit on the end of the

shaft.

It took a couple of days to work everything out and machine it up, which i suppose wasn't

to bad.

The clutch springs are now rocker springs from a GSXR1100, which if you've ever felt them

you know that theres not much pressure needed compared to a clutch spring to compress

them.

The clutch is now as light as a feather, as 85% of the pressure is now applied by the

weighted arms.

No more sore wrists and fingers..........

Mark. |

|